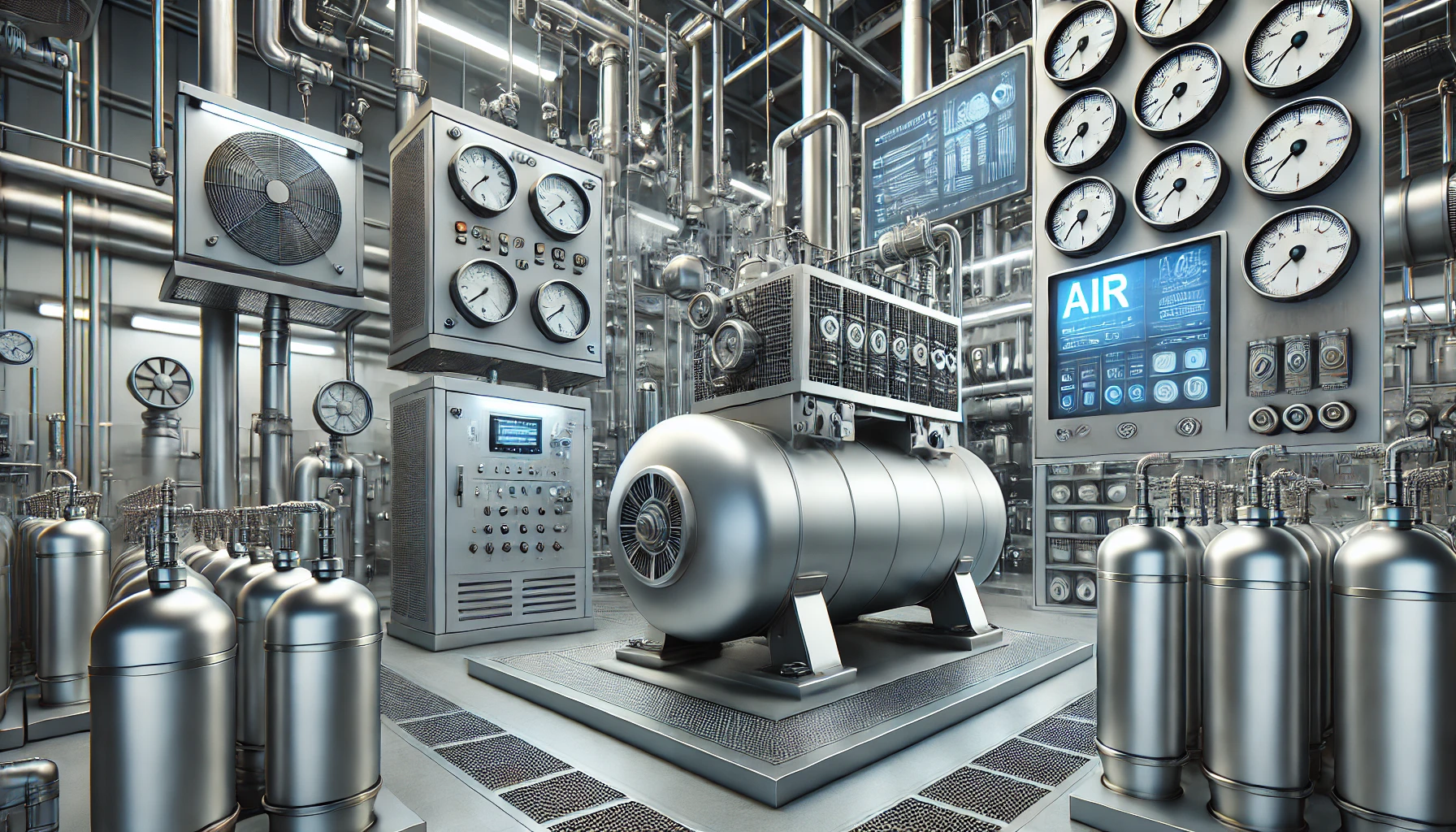

Air compressors are vital tools used across various industries and scientific fields, from manufacturing to environmental studies. One interesting aspect often overlooked is the abiotic factor of the air compressor. This term refers to the physical factors that influence the behavior of air during compression. Understanding these factors is essential for improving air compression efficiency, safety, and performance. In this post, we’ll explore the air compressor abiotic factor in depth, discussing everything from its impact on systems to real-world examples and the math behind air compression.

Biographical Table

| Term | Description |

|---|---|

| Abiotic Factors | Non-living elements that influence ecosystems or systems. |

| Air Compression | The process of increasing air pressure by reducing its volume. |

| Boyle’s Law | A fundamental principle describing the inverse relationship between pressure and volume at constant temperature. |

| Compression Factor | The ratio of air’s volume at standard conditions to its volume under compression. |

What is the Air Compressor Abiotic Factor?

The air compressor abiotic factor involves the non-biological elements affecting the behavior of air during compression. These factors are crucial in understanding how air behaves when subjected to high pressures, such as temperature, volume, and pressure. In simple terms, abiotic factors are the physical forces that affect the air when an air compressor compresses it.

Key Components of the Abiotic Factor

- Pressure: The force applied to air molecules when they are compressed.

- Temperature: The heat generated during compression, influencing air’s density.

- Volume: The amount of space that air occupies, which decreases as it is compressed.

- Humidity: The amount of water vapor present in the air, which can change during compression and affect performance.

These abiotic factors work together, and their interaction determines how efficiently the compressor operates.

How Air Compressors Influence Abiotic Factors

Air compressors manipulate these abiotic factors to increase the air pressure inside a container, which can have various consequences on the environment or system. Some of the main influences include:

- Temperature Rise: As air is compressed, its molecules move faster, generating heat. If not managed correctly, this temperature increase can affect surrounding equipment and even create safety hazards.

- Changes in Air Density: Compression reduces the volume of the air, thereby increasing its density. This change in density affects air flow and energy efficiency.

- Condensation: When air is compressed, its temperature may rise, causing water vapor to condense. This moisture can damage equipment if not properly handled or removed.

These influences explain why air compressors are often equipped with cooling mechanisms, moisture separators, and pressure regulators to effectively manage abiotic factors.

How to Obtain the Air Compressor Abiotic Factor

Obtaining the air compressor abiotic factor involves several steps. It’s crucial to measure and monitor the physical parameters that influence air compression to optimize performance and maintain safety standards.

Tools and Methods:

- Pressure Gauges: These instruments measure the pressure within the compressor, providing valuable data on the amount of force being exerted.

- Thermometers and Temperature Sensors: These sensors are essential for gauging the temperature increase during compression.

- Hygrometers: These are used to measure humidity levels in compressed air, which can affect performance and system longevity.

Practical Steps:

- Install the necessary sensors on your compressor system.

- Monitor the parameters: Regularly check the pressure, temperature, and humidity levels during operation.

- Adjust settings: Based on your readings, adjust compressor settings to ensure that the abiotic factors remain within optimal ranges.

By carefully managing these variables, you can ensure your air compressor operates efficiently while minimizing equipment wear and tear.

Unlocking the Air Compressor Abiotic Factor

Unlocking the air compressor abiotic factor requires a deeper understanding of how to control the physical parameters for specific needs. Certain systems, like industrial air compressors or HVAC units, demand precise control over abiotic factors to function optimally.

Key Considerations for Unlocking:

- Environmental Adjustments: For example, cooling systems can be installed to manage temperature increases due to compression.

- Calibration: Ensuring that the compressor settings match the operational environment and desired output is essential.

- Advanced Monitoring: High-tech monitoring systems can track and adjust the abiotic conditions in real-time for maximum efficiency.

By applying these methods, professionals can “unlock” the full potential of their compressors, ensuring they work in harmony with their surrounding environment.

The Air Compression Equation

Understanding the air compression equation is essential for comprehending how air behaves under different pressures. The primary equation governing air compression is Boyle’s Law, which states:

P1×V1=P2×V2P_1 \times V_1 = P_2 \times V_2

Where:

- P1P_1 and P2P_2 are the initial and final pressures,

- V1V_1 and V2V_2 are the initial and final volumes.

This equation demonstrates that pressure and volume are inversely related for a given amount of air—when you decrease the volume of air (compress it), the pressure increases, and vice versa.

Additional Considerations:

- Ideal Gas Law: PV=nRTPV = nRT, which combines pressure, volume, and temperature for more complex calculations.

- Compression Factor: The compression factor accounts for real-world inefficiencies, like leaks or imperfect gas behavior.

By applying these equations, engineers can predict how air will behave under different compression scenarios and optimize air compressors accordingly.

Air Compressor Code Requirements

When dealing with air compressors, there are specific code requirements to ensure safety and environmental compliance. These codes dictate how compressors should be designed, installed, and maintained.

Key Air Compressor Codes:

- ASME Boiler and Pressure Vessel Code: Governs the design and construction of pressure vessels.

- NFPA 69: Covers the safety of air compressors to prevent explosive hazards.

- OSHA Regulations: Enforces safety practices in workplaces using air compressors.

Meeting these codes ensures that compressors operate safely, reducing risks of accidents due to pressure buildup, equipment failure, or fire hazards.

Air Can Be Compressed: Real-Life Example

One of the simplest demonstrations of the air compressor abiotic factor is seeing air compressed in action. Take the example of a diving tank: As air is compressed into the tank, its volume shrinks, and the pressure increases. This principle applies to various industries:

- Manufacturing: In factories, air compressors are used to power pneumatic tools. The abiotic factors of pressure and temperature affect the efficiency and power output of these tools.

- Medical Field: Air compressors provide the pressure necessary for ventilators in hospitals, where maintaining the correct abiotic factors is critical for patient safety.

These examples show how understanding the air compressor abiotic factor can make a significant difference in the reliability and efficiency of air-powered systems.

Compression Factor of Air

The compression factor of air is a critical concept in air compression systems. It defines the relationship between the actual behavior of air during compression and the idealized predictions of gases.

| Factor | Impact on Air Compression |

|---|---|

| Pressure | Directly affects how much air can be compressed. |

| Temperature | A rise in temperature can cause air to expand. |

| Volume | Reducing air volume increases pressure. |

The compression factor is particularly important when dealing with air under extreme conditions, such as in industrial or scientific applications.

Where to Find the Air Compressor Abiotic Factor

The air compressor abiotic factor is critical for maintaining effective systems. You’ll find these factors in numerous environments, including:

- Industrial Sites: Factories and plants that use heavy-duty air compressors.

- Scientific Labs: Research labs studying the behavior of gases under pressure.

- HVAC Systems: Air conditioners and refrigeration units that rely on air compression.

Measuring and Monitoring Locations:

- Digital Pressure and Temperature Monitors: Installed in air compressors to continuously measure key abiotic factors.

- Environmental Sensors: Used to track humidity and air quality in systems requiring high precision.

Abiotic Factors of Air

Air’s abiotic factors extend beyond compression to include the atmospheric conditions that influence its behavior. Key abiotic factors of air include:

- Atmospheric Pressure: This external pressure influences the ease with which air can be compressed.

- Humidity: The moisture in the air affects both compressor performance and air quality.

- Temperature: Ambient temperature affects the air’s behavior during compression and expansion.

Each of these abiotic factors can play a role in the efficiency and safety of air compression systems.

Why Is Air Abiotic?

Air is classified as abiotic because it consists of non-living elements, such as nitrogen, oxygen, and trace gases. Unlike living organisms, air doesn’t have biological processes or life cycles. Understanding this distinction helps in managing how air is treated in mechanical and industrial applications.

Conclusion

The air compressor abiotic factor is an essential concept for anyone working with compressed air systems. By understanding the physical properties of air, you can optimize compressor performance, improve safety, and ensure that systems function efficiently. Whether you’re measuring pressure, managing temperature, or dealing with humidity, keeping track of these abiotic factors is critical. With the proper knowledge and tools, you can unlock the full potential of air compressors and use them to their maximum capacity in any setting.