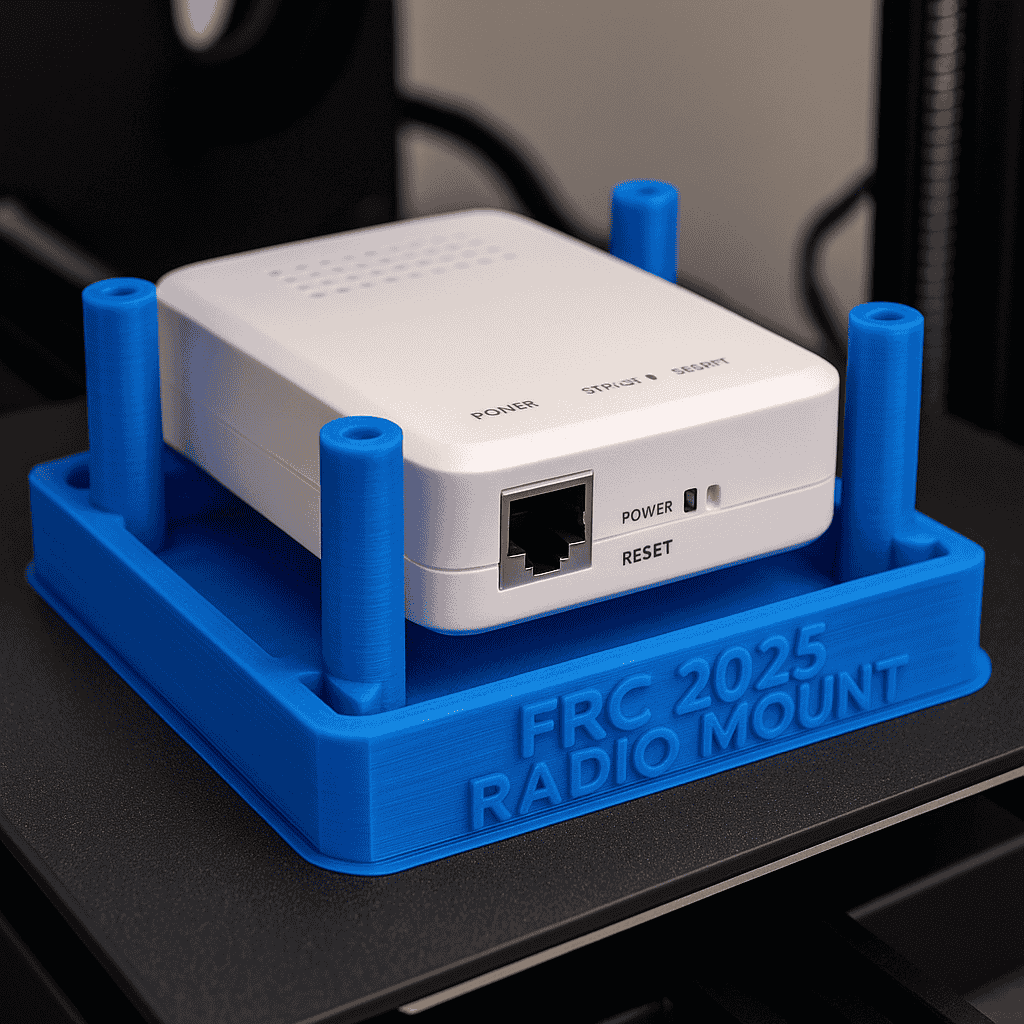

In the world of competitive robotics, especially within the FIRST Robotics Competition (FRC), every small part matters. One essential but often overlooked component is the frc 2025 radio mount 3d print. This small but vital part ensures that the team’s radio device is securely fastened to the robot, enabling seamless communication during intense matches.

As 3D printing technology becomes more accessible, teams are turning to customized solutions to meet their unique needs. Designing and printing a radio mount specifically for FRC 2025 offers flexibility, cost-effectiveness, and innovation.

In this article, we’ll dive deep into what makes a good radio mount, how to design one, and why 3D printing is revolutionizing how teams approach this challenge.

Why a Good Radio Mount Matters in FRC 2025

When competing in FRC 2025, communication reliability is critical. The radio is the link between the robot and the driver station. If the mount is weak, misaligned, or vibrates too much during gameplay, it can cause disconnections — resulting in match losses.

The FRC 2025 radio mount 3d print offers a sturdy, lightweight, and custom-fit solution. A well-designed mount can absorb shocks, minimize vibrations, and protect sensitive components from damage during high-impact collisions on the field.

Teams that invest time in creating a durable radio mount through 3D printing give themselves a competitive edge, ensuring that no technical errors hinder their performance.

Key Features to Include in Your FRC 2025 Radio Mount Design

When planning your frc 2025 radio mount 3d print, there are several critical design elements you should consider:

- Strength and Durability: Use robust materials like PETG or Nylon to resist breaking under stress.

- Lightweight Design: Keep the mount lightweight to maintain the robot’s overall speed and maneuverability.

- Vibration Dampening: Include design features such as rubber inserts or flexible arms to minimize vibrations.

- Easy Installation: Design with mounting holes that match standard FRC robot frames and allow quick attachment and removal.

- Wire Management: Built-in channels or clips to neatly route wires and prevent accidental unplugging during matches.

Choosing the Right Material for 3D Printing

Material selection is crucial for the success of your radio mount. Here’s a quick comparison of popular 3D printing materials:

- PLA: Easy to print but brittle; not ideal for high-stress FRC applications.

- PETG: Offers excellent strength and flexibility — a great balance for FRC use.

- ABS: Strong but can warp during printing; requires a heated bed.

- Nylon: Extremely durable and flexible, but can be tricky to print without the right equipment.

3D Printing Tips for FRC 2025 Radio Mounts

Even the best design won’t perform well if the print quality is poor. Keep these tips in mind:

- Use high infill: Aim for at least 50% infill for added strength.

- Layer height: A layer height of 0.2mm gives a good balance between detail and strength.

- Temperature settings: Make sure your printer settings match the material manufacturer’s recommendations.

- Print orientation: Print the part in a direction that supports maximum stress tolerance.

- Popular 3D Models and Where to Find Them

If you don’t have the time or resources to design from scratch, many high-quality designs are already available online. Some great sources include:

- Thingiverse: Free community-made 3D models for FRC radio mounts.

- GrabCAD: Engineering-focused platform offering detailed CAD files.

- PrusaPrinters: Offers reliable, competition-tested designs.

- Team GitHubs: Many FRC teams share their designs after each season.

How to Customize Your Radio Mount Design

Sometimes standard designs won’t meet your robot’s specific needs. In that case, learning basic CAD (Computer-Aided Design) skills can be incredibly helpful.

Softwares like Fusion 360, SolidWorks, and TinkerCAD make it easier than ever to tweak models or even create your own from scratch.

Customization ideas for your frc 2025 radio mount 3d print might include:

- Additional protective covers for antennas.

- Extra cooling vents to prevent radio from overheating.

- Snap-fit designs for tool-free installation.

Testing and Installing Your 3D Printed Radio Mount

Once your mount is printed, it’s essential to test it thoroughly before match day:

- Shake Test: Simulate match vibrations and impacts.

- Drop Test: Minor drops shouldn’t break the mount.

- Fit Test: Check alignment with the radio and mounting holes.

- Connection Test: Ensure cables stay firmly connected even under movement.

Cost and Time Benefits of 3D Printing Your Own Mount

Buying pre-made mounts or creating mounts from traditional materials (like aluminum) can be expensive and time-consuming.

With a good 3D printer, your team can:

- Produce a radio mount for under $5 in material costs.

- Print multiple backups in case one breaks.

- Rapidly prototype and improve designs within a few days.

Over the course of the FRC season, the savings in both money and time with a frc 2025 radio mount 3d print add up quickly.

Final Thoughts

3D printing is more than just a fun side project; it’s becoming a necessity for high-performing FRC teams.

By investing a little time into designing or downloading a quality frc 2025 radio mount 3d print, your team will gain. Hope this guide will be helpful for you.

FAQs

Q1: Can I use any 3D printer to create an FRC 2025 radio mount?

Yes, most FDM 3D printers are suitable for this purpose. Just make sure your printer offers good precision and strength to produce a durable and reliable mount.

Q2: What is the best filament material for an FRC radio mount?

PETG and carbon fiber-infused filaments are considered the best choices because they offer a balance of strength, flexibility, and impact resistance, making them ideal for competition environments.

Q3: If my 3D printed mount breaks, can I quickly produce a replacement?

Absolutely! That’s one of the biggest advantages of 3D printing. If you have the STL file ready, you can reprint a new mount within a few hours.

Q4: What is the most important thing to consider when designing an frc 2025 radio mount 3d print?

The most important factor is ensuring the mount holds the radio securely while keeping all wiring and connector ports easily accessible for quick maintenance during matches.

Q5: Can I use pre-existing designs instead of creating my own?

Yes, many teams share their designs online. You can download, modify, and print a pre-made design to save time and ensure compatibility with your specific setup.